If you have a system that tracks costs automatically, however, the accuracy of normal costing always beats out standard costing. Understanding the root causes of variances is essential for effective variance analysis. For instance, a favorable material variance might indicate successful negotiations with suppliers or more efficient use of raw materials. Conversely, an unfavorable labor variance could suggest issues such as lower productivity, higher wage rates, or unanticipated overtime. By delving into these underlying factors, businesses can identify specific areas that require attention and take corrective actions to improve performance.

Standard Costing Price Variance

- It facilitates continuous improvement efforts by identifying areas of inefficiency and supporting cost optimization initiatives.

- (6) Review of Cost Accounting System – Standard costing is a projection of the existing system of cost accounting.

- In adverse economic times, firms use the same efficiencies to downsize, right size, or otherwise reduce their labor force.

- Variance analysis helps identify cost discrepancies and supports cost management strategies.

- Furthermore, real-time insights enable companies to adapt swiftly to market fluctuations, staying competitive in dynamic environments.

- A production department that is focused on receiving immediate feedback about problems so that they can correct them quickly will be disappointed.

Large variances from the ideal are normal and difficult to manage by exceptions. Most managers feel that ideal standards tend to discourage even the most diligent workers. However, output in many companies is no longer determined by how fast labor works; rather, it is bookkeeping determined by the processing speed of machines. Some companies report variances and key operating data daily or even more frequently.

Income Statement Impact of Bad Standards

Make variance review a regular part of management meetings, with clear accountability for investigation and corrective action. Without this closing of the loop, variance analysis becomes an academic exercise rather than a management tool. Start with thorough system design, defining how standards will be established, documented, and used. Create standard cost records, variance reports, and investigation procedures before you need them. Start with material standards by determining both expected prices and quantities. Purchasing records, supplier quotes, and engineering specs provide your foundation.

Real-time Integration and Dynamic Standards

One of the primary elements in standard costing is the establishment of standard costing system standard material costs. This involves determining the expected cost of raw materials required for production. Companies often rely on past purchase prices, supplier quotes, and market trends to set these standards. Accurate material costing is crucial as it directly impacts the overall production cost and profitability. The production that is acceptable (not rejected products) and which is assigned manufacturing costs of direct materials, direct labor, and manufacturing overhead.

The fixed manufacturing overhead volume variance is the difference between the amount of fixed manufacturing overhead budgeted to the amount that was applied to (or absorbed by) the good output. If the amount applied is less than the amount budgeted, there is an unfavorable volume variance. This means there was not enough good output to absorb the budgeted amount of fixed manufacturing overhead. If the amount applied to the good output is greater than the budgeted amount of fixed manufacturing overhead, the fixed manufacturing overhead volume variance is favorable. A portion of these fixed manufacturing overhead costs must be allocated to each apron produced.

Help to Provide Guidance for Improving Efficiency

If your competitive advantage comes primarily from driving down production costs, this method provides the visibility you need. Medium to large manufacturers typically have the resources needed to implement and maintain standard costing properly. They can justify dedicating staff time to develop standards, track variances, and keep the system current. Updating standards requires significant effort—collecting market data, conducting time studies, and revising accounting systems, which many companies struggle to prioritize. When standards drift too far from reality, the resulting variance reports become meaningless noise rather than actionable intelligence.

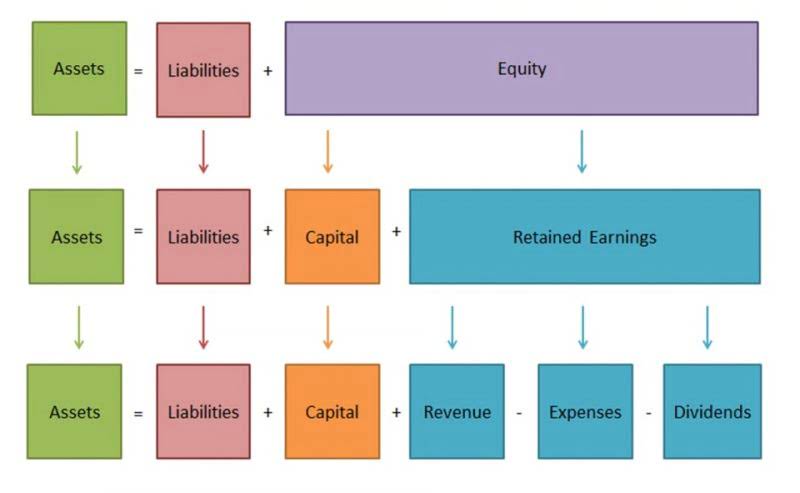

Standard costing is a cost accounting method that sets pre-established standards for costs and performance. The variance derived is then used by the company’s management for knowing and correcting the cause, making a further estimation for the coming years, and decision making related to business. It almost always varies from the actual costs because the situation keeps changing, involving different unpredictable factors.

Balance Sheet

- All future actual costs are expected to be close to the estimates calculated for standard costs.

- In this technique the management of the business calculates a predetermined estimated cost for a product at the start of an accounting period.

- It compares the expenses incurred to the standard values and analyzed variation so performance may be monitored.

- The second objective of standard cost is to help the management in exercising control over the costs through the principle of exception.

- By setting these standards, businesses can monitor labor efficiency and identify areas for improvement.

- For the past 52 years, Harold Averkamp (CPA, MBA) has worked as an accounting supervisor, manager, consultant, university instructor, and innovator in teaching accounting online.

The aim of calculating this cost of a product is to measure the performance of the business and control any deviations from the standard costs. This cost is used as a benchmark for monitoring and controlling the performance of the business in the future. Assume your company’s standard cost for denim is $3 per yard, but you buy some denim at a bargain price of $2.50 per yard. For each yard of denim purchased, DenimWorks reports a favorable direct Restaurant Cash Flow Management materials price variance of $0.50.

Tinggalkan Balasan